Located in La Chaux-de-Fonds, an industrial hub in the canton of Neuchâtel recognized for its pivotal role in Swiss watchmaking, Breitling, one of Switzerland's most acclaimed watchmakers, has provided a comprehensive and transparent look inside its manufacturing facilities. This rare access was granted to Teddy Baldassarre, who was joined by the brand's chief operating officer, Daniel, to explore the techniques perfected over Breitling’s 140-plus years of history. The facility, known as the manufacturer chronometry, focuses on movement development, production, and homologation, covering everything from R&D and design to final assembly.

The creation of a Breitling timepiece begins at the technical office, where the movement’s conception, construction, and simulation lay the groundwork for prototyping. When discussing the development of new models, Daniel provided Teddy Baldassarre with an example: creating a perpetual calendar based on the B01 chronograph movement. The core challenge was building a perpetual calendar complication atop a chronograph base while ensuring the information displayed on the dials remained very readable. Beyond functionality, the design phase must equally prioritize the movement's reliability, cost, assembly methods, and, most importantly, the long-term repairability for customers globally.

Supporting this development is the laboratory, where raw materials are inspected, and surface treatments or component flaws are analyzed. Daniel noted that they are constantly "chasing perfection". If unexpected stains appear on an element, such as the 22-karat gold oscillating weight, the lab analyzes the substance, sometimes using tools based on the periodic table, to identify the cause. Based on this analysis, they provide an action plan—which might be as simple as cleaning the weight or require an adjustment to an earlier process step—to correct the mistake. Teddy Baldassarre noted the "deep magnification" used in the lab, emphasizing that the level of detail goes almost beyond what the naked eye would notice.

Related article - Uphorial Shopify

Breitling - How They're Made

A critical phase is durability testing, which includes rigorous aging simulations. One test simulates 16 years of pusher use by running non-stop for three days. If a failure occurs, the company performs analysis to understand the root cause, whether it stems from dust, material quality, or assembly errors. High-speed observation is also used to analyze the movement's precision and stability. The chronograph reset, for instance, is captured at 4,500 frames per second. As Teddy Baldassarre remarked, this high-speed video reveals a surprising reality: the seconds hand goes "long way back" before eventually stabilizing, rather than settling instantly at 12:00 as it appears to do during normal use. The design challenge is offering hands that are both thin and aesthetically delicate while remaining highly resistant to a customer's repeated use over a period of at least 16 years. To ensure product liability, every new watch is subjected to shock tests, including one simulating a one-meter drop, which Daniel calls "the worst one".

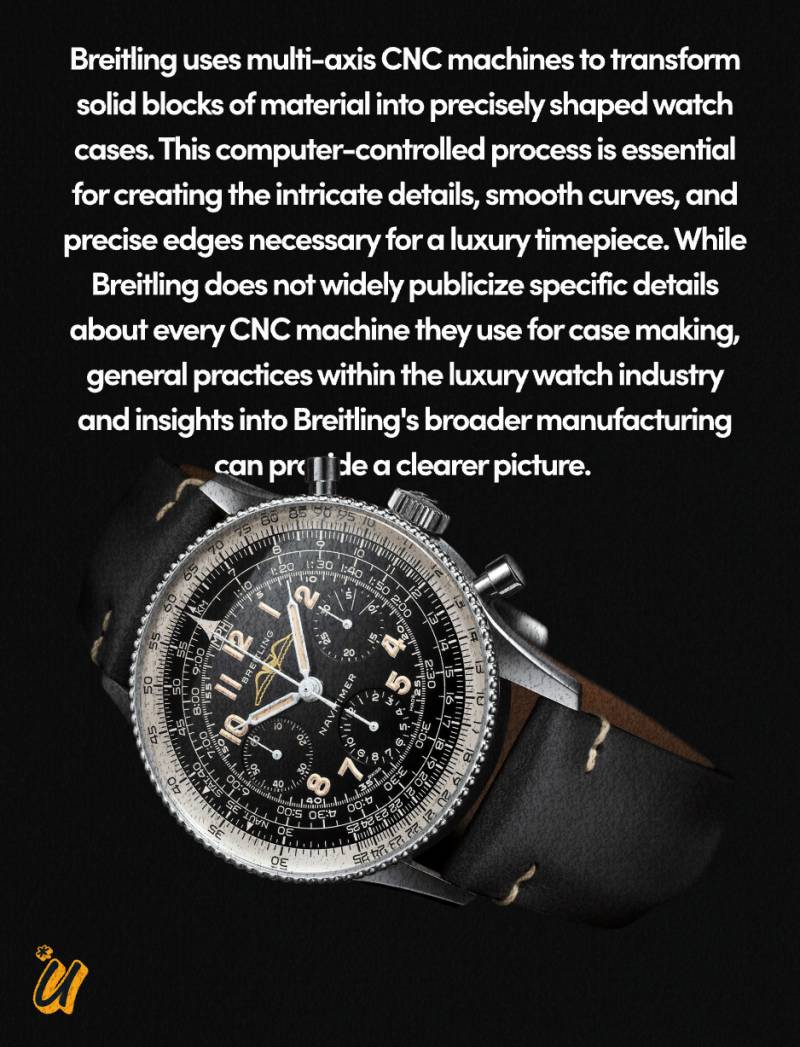

Moving into the micromechanics workshop, Breitling uses CNC five-axis machines to produce cases, bezels, crowns, and pushers, as well as some movement components. The facility also features electro-erosion machines that use 60 kilometers of wire to efficiently cut material and create multiple components from the same plate. Breitling strategically maintains the know-how to produce critical components, such as the balance wheel, internally using turning machines. The main reason for this internal production is to shorten the development cycle and improve time to market, allowing for rapid iteration between technical design, in-house prototyping, testing, modification, and re-homologation.

The movement production starts in the milling workshops, where components like the main plate and bridges are produced in four main steps: milling, separating the components from the plate, sand blasting to remove milling marks, and high-pressure water jet deburring. Given that a B01 movement main plate interacts with 350-plus components, this requires "extreme" precision, as the main plate is the most complex component due to all the pivot points. To ensure perfection, production runs 24 hours a day, and new automated control equipment has multiplied the number of quality checks by at least ten. Next is pre-assembly (T0), where components are brought together. Operations vary from using manual press tools to utilizing automated equipment for complex tasks like garnishing—setting rubies and pins on bridges. The 300-plus components of a chronograph are bundled into roughly 30 kits for the final assembly line. Before final assembly, all incoming components are subject to 100% inspection, including using automated barometers to check barrels and mainsprings to guarantee the power reserve.

The final assembly (T1) utilizes automatic lines with a conveyor belt system moving movement bases between stations. While some steps are quick, longer ones, such as the chronograph mechanism (14 different steps), require three parallel benches to balance the production flow and optimize timing. The room also handles specialized movements like the B19 perpetual calendar, which takes three or four times longer to assemble than a standard B01 and is handled by highly experienced watchmakers. Finally, the T2 casing workshop puts the movement into the case, adds the hands and dials (with delicate hand setting done in a laminar flow environment to avoid dust), and makes the watch head waterproof. The watch then undergoes final checks for water resistance and precision. Teddy Baldassarre concluded by thanking Daniel for the access and transparency, noting that he recognizes and greatly appreciates the effort in showing every single process involved in the manufacture.