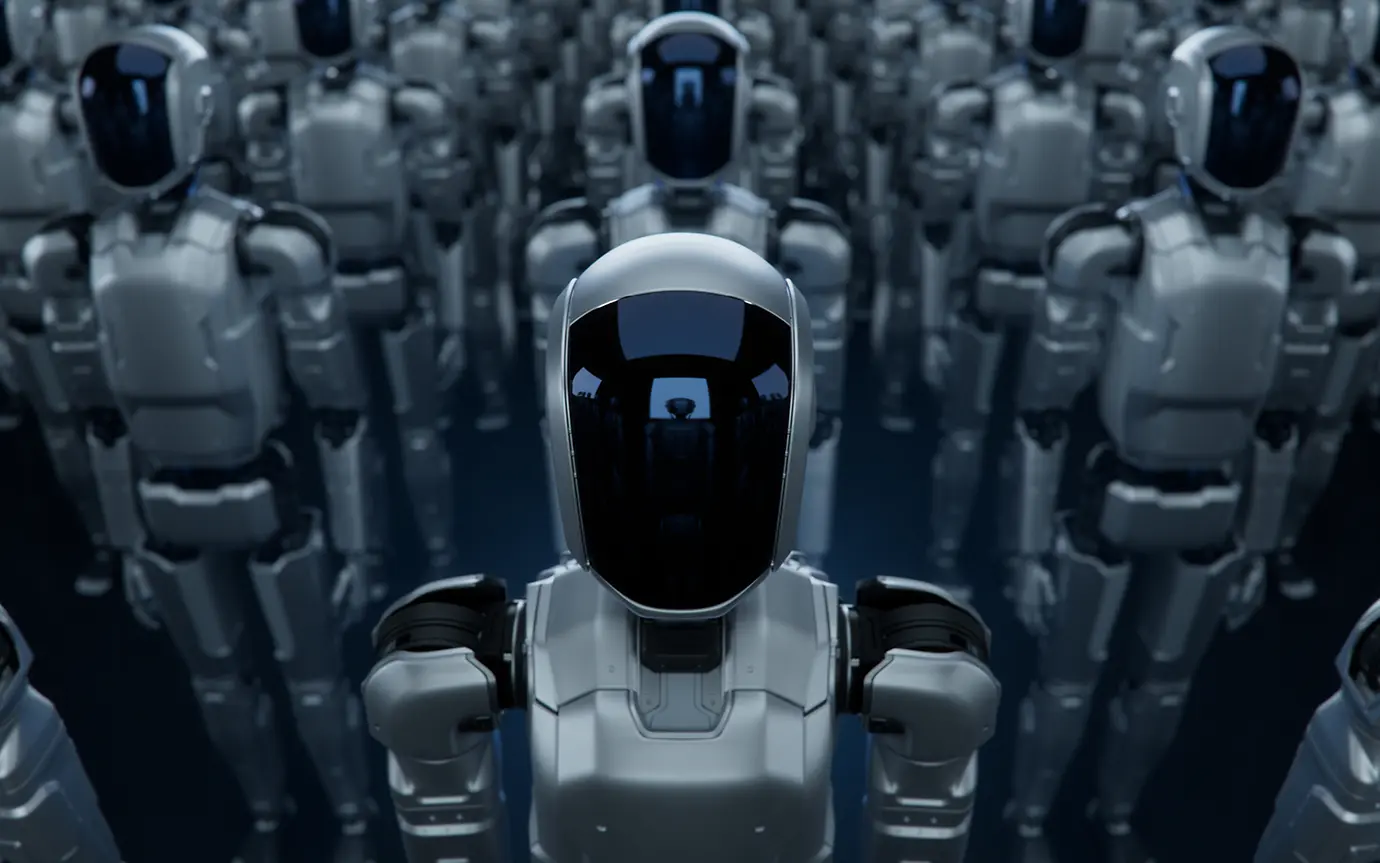

New China TV recently provided an exclusive, high-definition look inside the Lingong Pilot Free Trade Zone in Shanghai, where the mass production of humanoid robots has officially entered its inaugural year. Correspondent Suning, broadcasting for the agency, documented a landmark delivery ceremony for AGI Bot’s 5,000th unit, an event featuring hundreds of "Expedition A2" models standing in formation like a scene from a science-fiction epic. This facility, which only launched in April 2024, has rapidly scaled its operations through a partnership with MBHS, a firm with three decades of automotive experience. By transferring rigorous automotive quality control systems—such as FEMA and real-time material tracking—to the robotics sector, the factory ensures that every humanoid machine maintains a stable and consistent performance standard.

The manufacturing of these complex machines involves dozens of steps divided into five core modules: the joints, upper limbs, lower limbs, torso, and final assembly. New China TV’s live stream captured the moment robots received their "souls" through software installation, granting them the ability to walk, speak, and interact. Before a robot is deemed ready for delivery, it must undergo approximately 40 distinct tests, including mechanical limit stress tests for every joint. Safety remains a paramount concern as these machines move into human workplaces; consequently, each unit is equipped with LIDAR, cameras, and IMUs, allowing them to provide rapid responses to unexpected scenarios and stop immediately when a human path is detected. A standout feature of the quality assurance process is the four-hour "aging test," where robots are tasked with navigating real-world materials like marble and ramps to guarantee reliability in environments such as museums, exhibition halls, or banks.

Related article - Uphorial Sweatshirt

Reaching the 5,000-unit milestone marks a critical pivot from laboratory research to commercial viability. AGI Bot director Mr. Tao explained to New China TV that this volume allows the company to move beyond simple prototypes and into real-world applications like reception, guidance, and light manipulation, such as picking up bottled water or snacks. Beyond immediate utility, mass production creates a vital "data flow". As thousands of robots operate in diverse scenarios, they collect massive amounts of real-world data that are fed back into foundation models, making the next generation of machines progressively more intelligent and capable.

The vision for AGI Bot extends far beyond the Chinese market, with the company already delivering units to Europe and Japan. To facilitate this global reach, the robots are currently capable of speaking seven foreign languages, with plans to expand to twenty by the end of the year. While humanoid robots are currently finding their footing in the commercial and entertainment sectors—often being rented for ceremonies and dancing shows—Mr. Tao suggests they could become a part of daily household life within the next five to ten years. For the coming year, the company aims to "add a zero" to its production numbers, targeting the assembly of tens of thousands of robots as the industry continues its rapid acceleration.

To understand the growth of this industry, one might view the factory as a high-tech nursery; while these robots are currently "growing like children" and learning simple tasks, the mass-production environment provides the constant nourishment of data and refined engineering they need to eventually mature into independent members of human society.